Underground

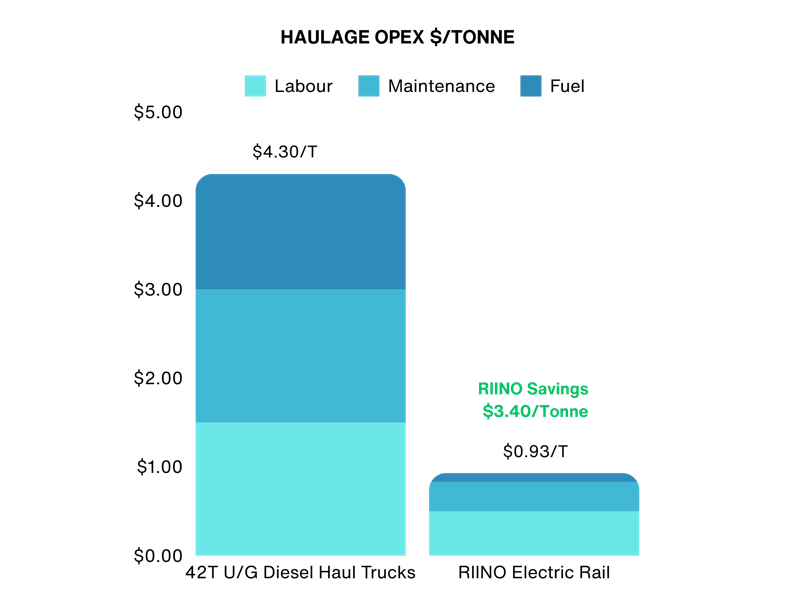

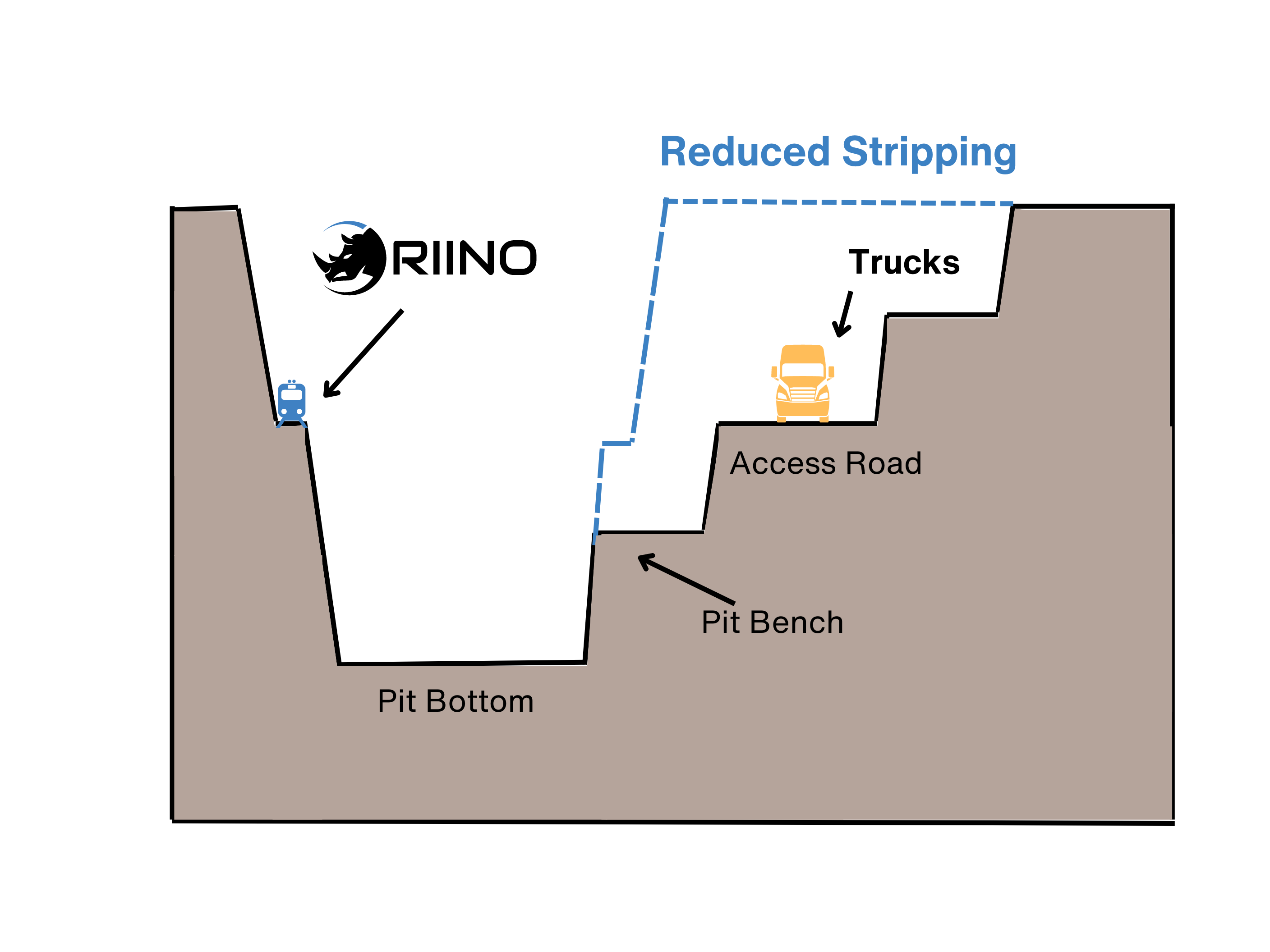

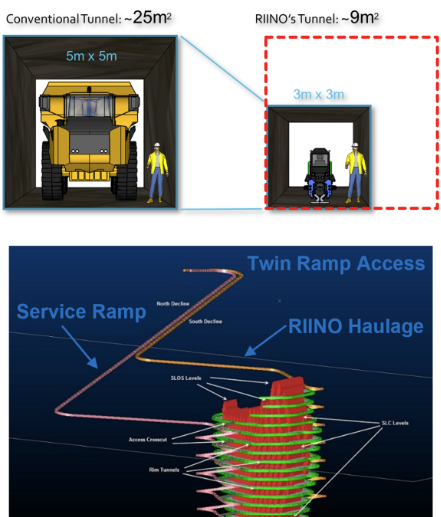

No haulage trucks = Small drift profile Reduced development schedule Faster development cycle times Earlier ore production Less ground support Less ventilation Less overall electrical consumption Minimal ore & waste rock rehandling