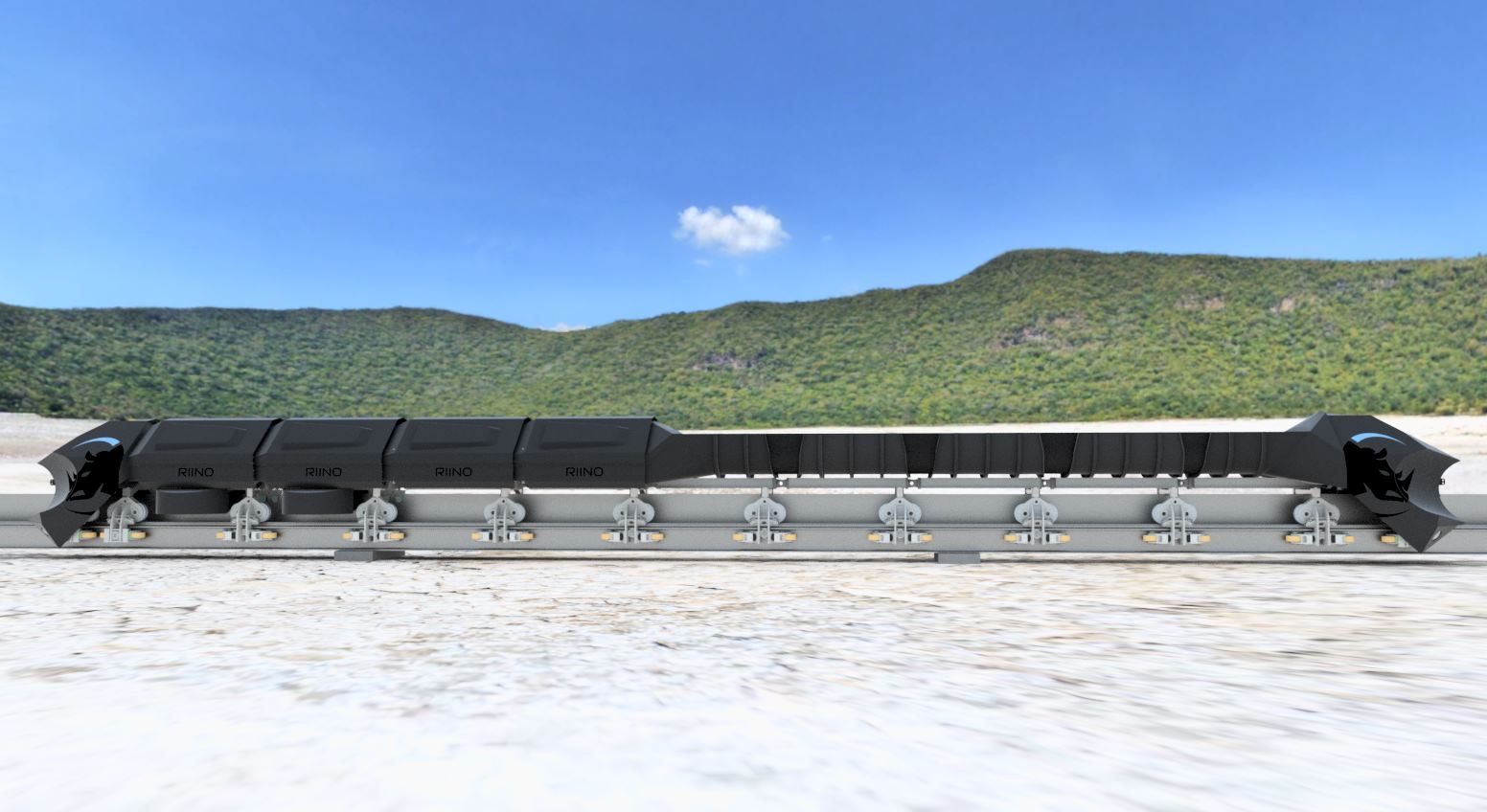

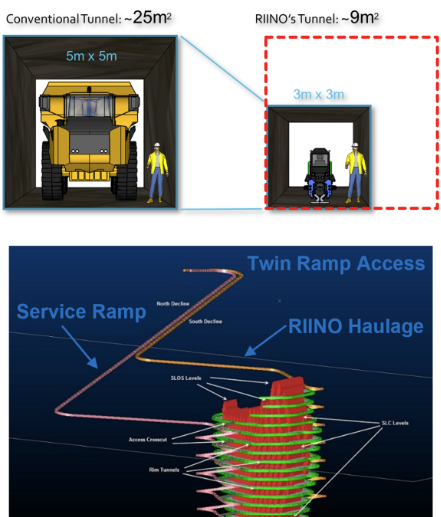

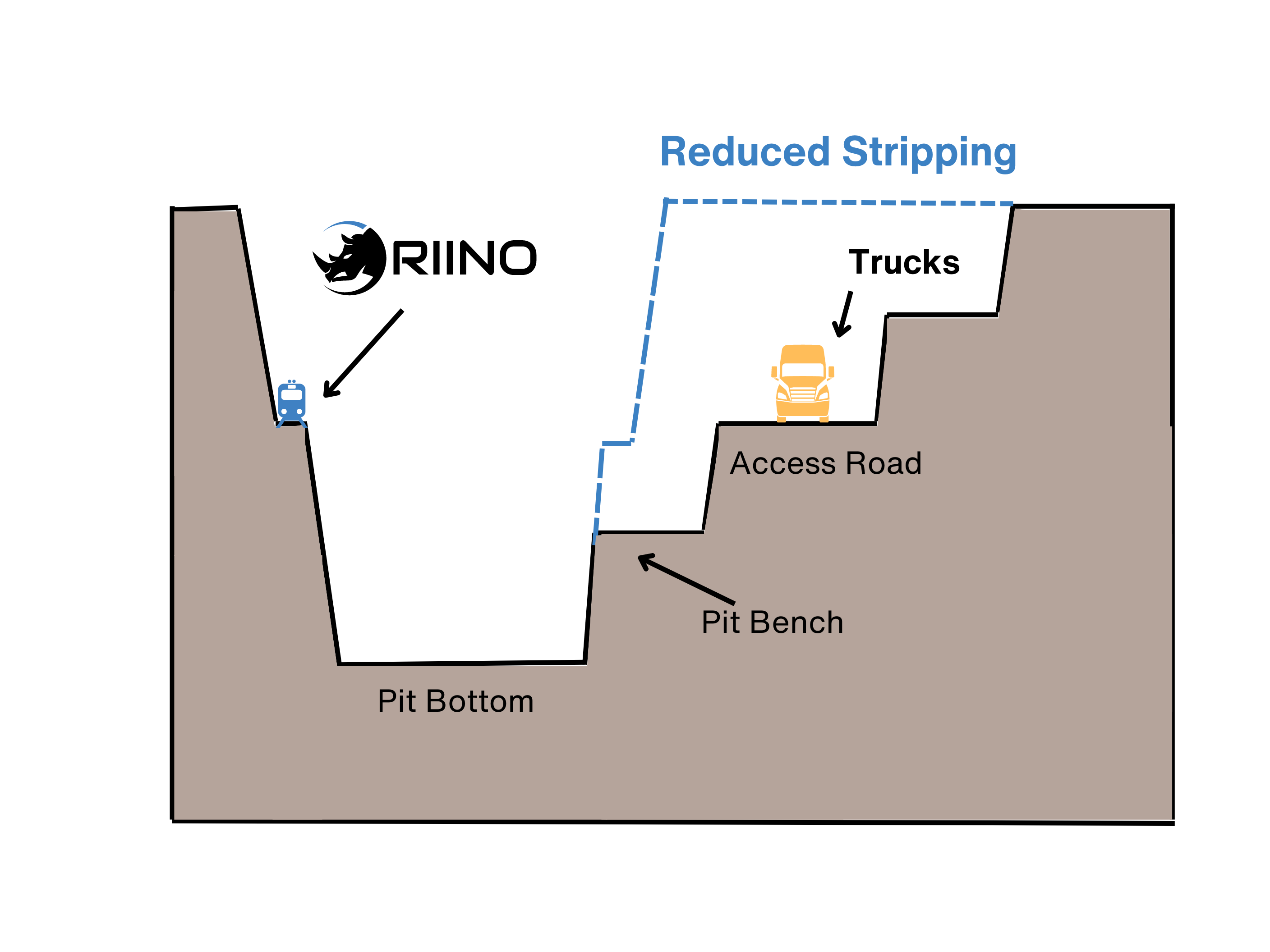

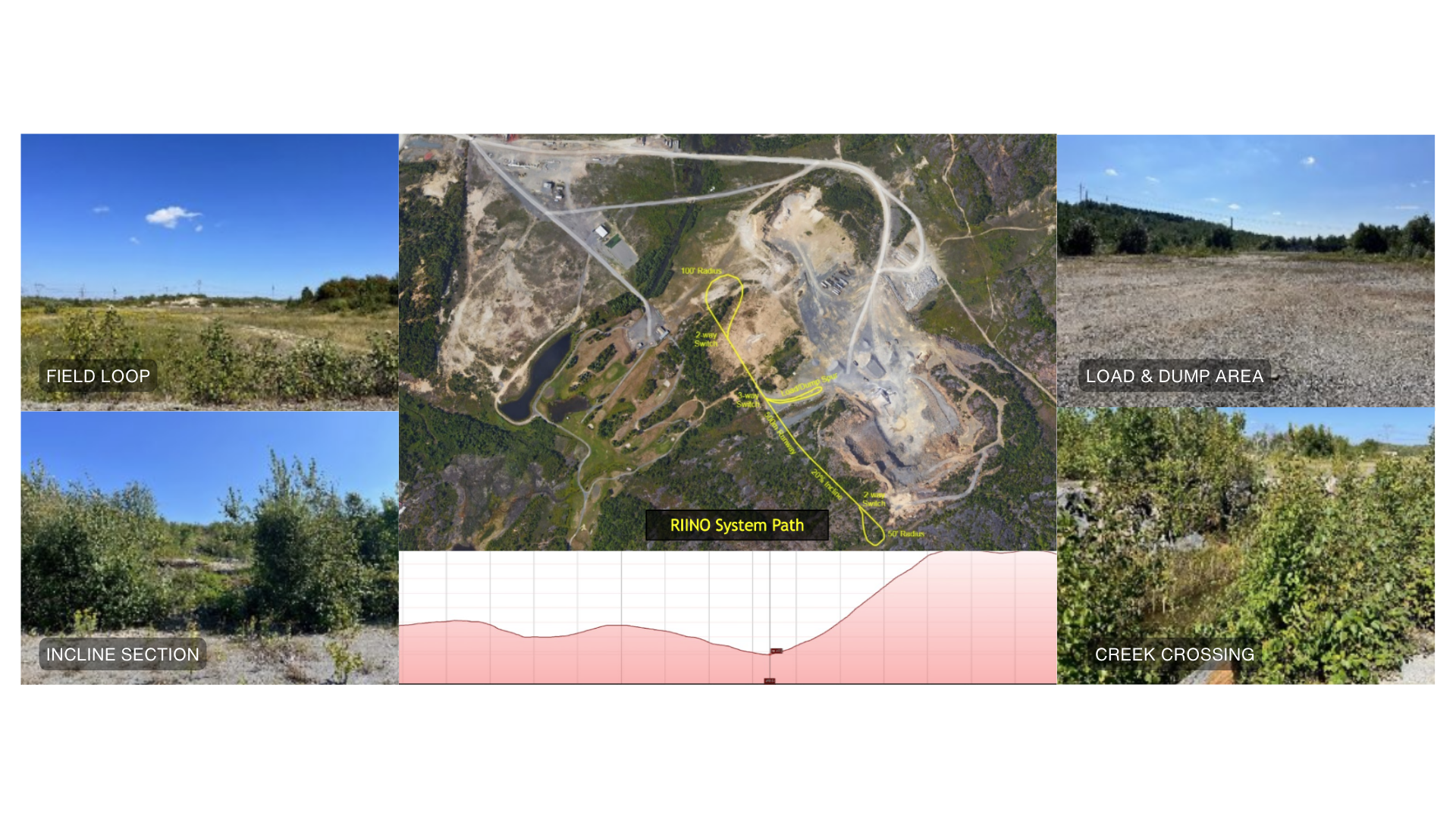

Underground & oPEN-PIT

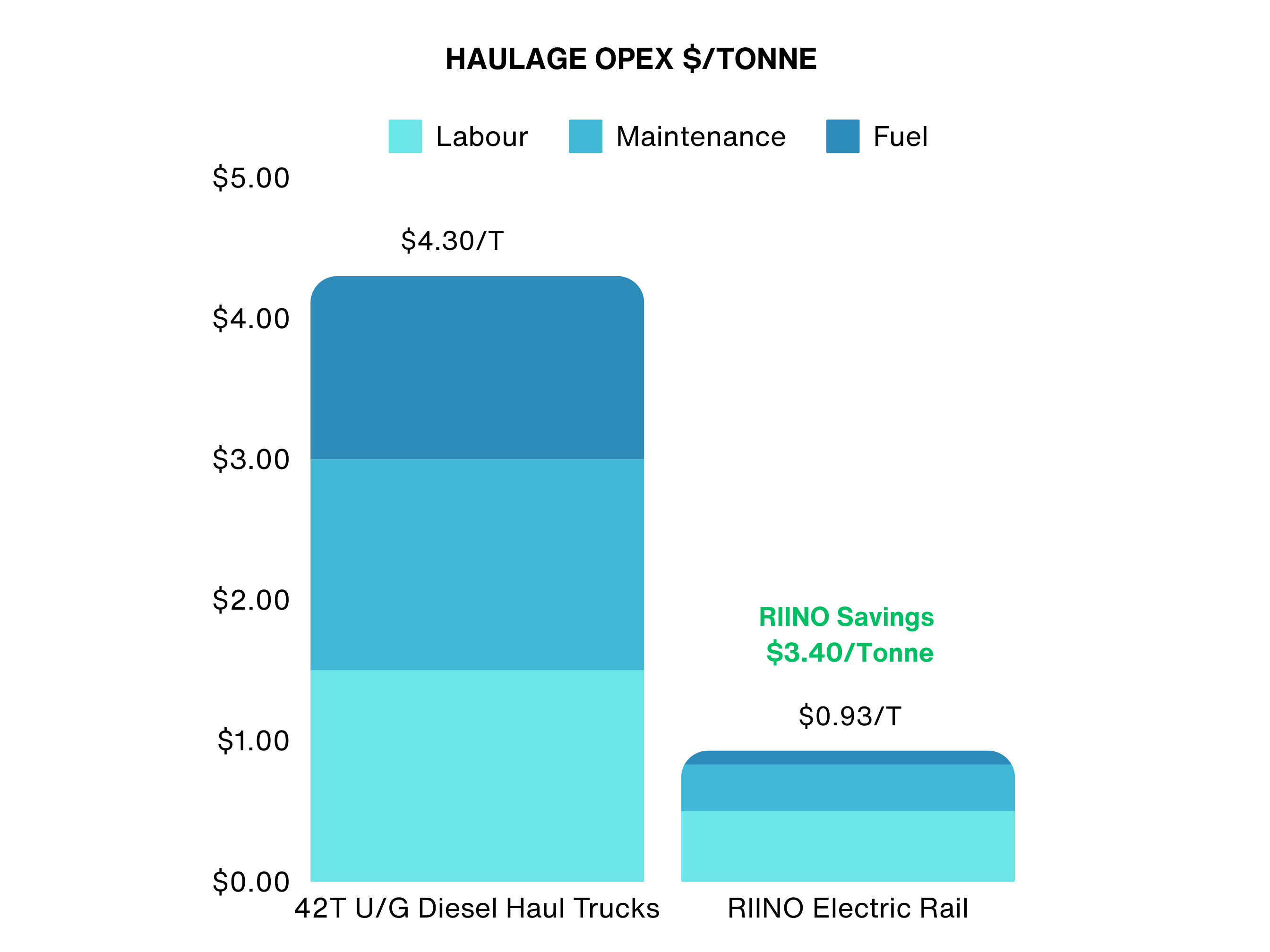

Lowered Haulage OPEX by

50% - 90%

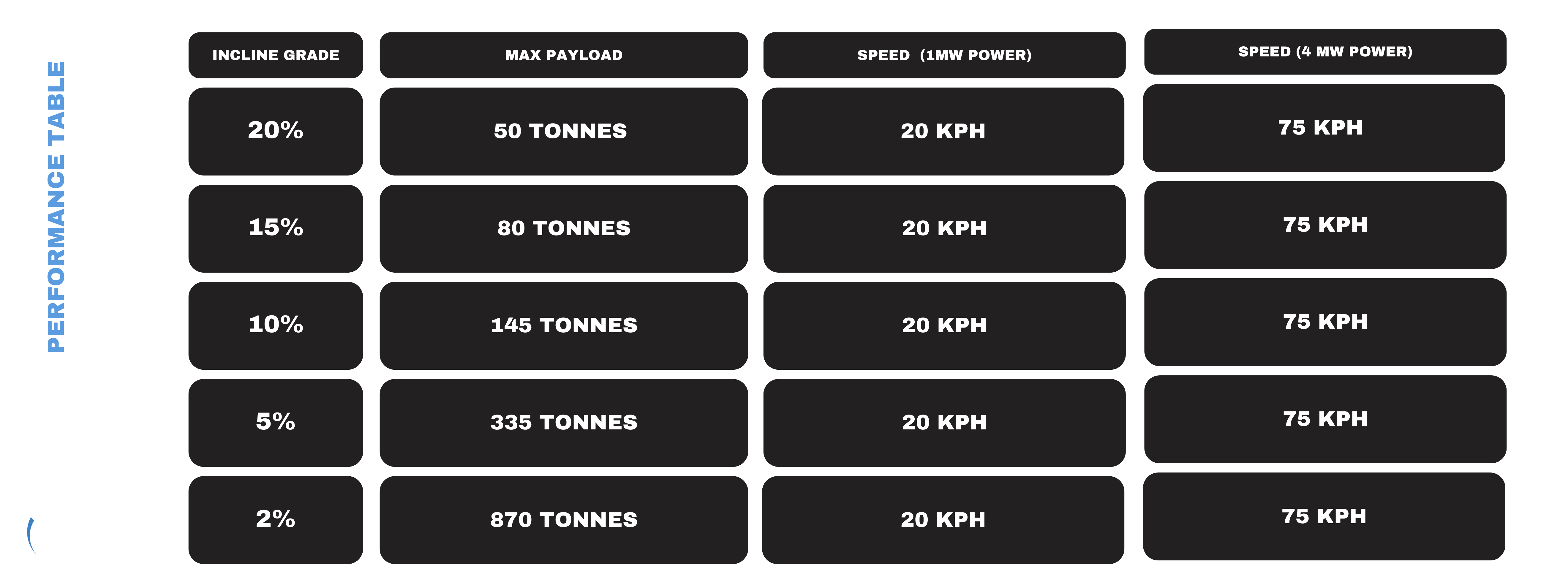

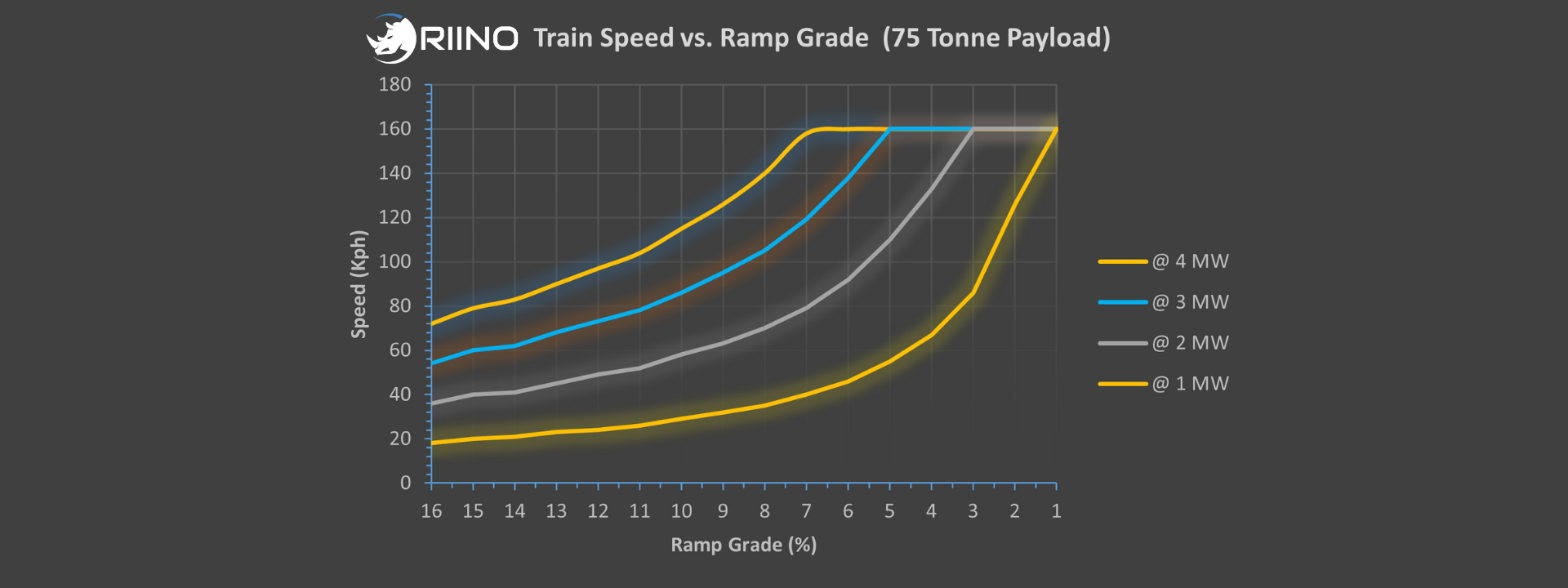

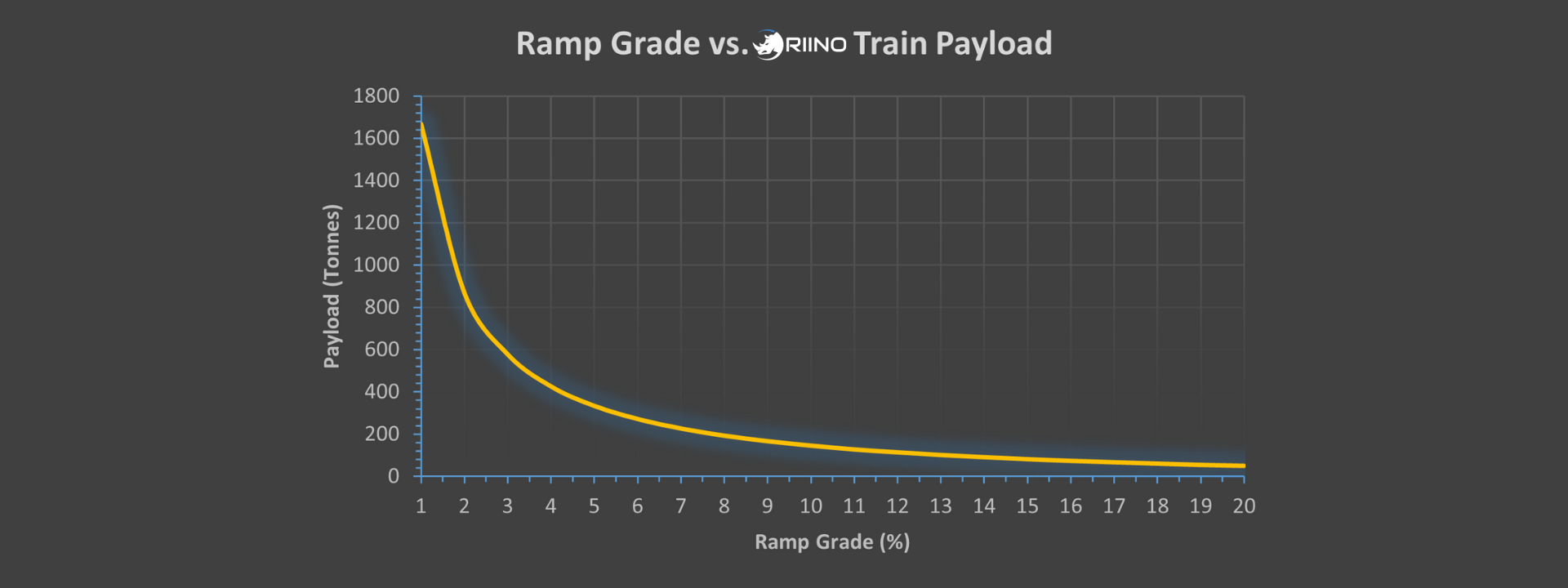

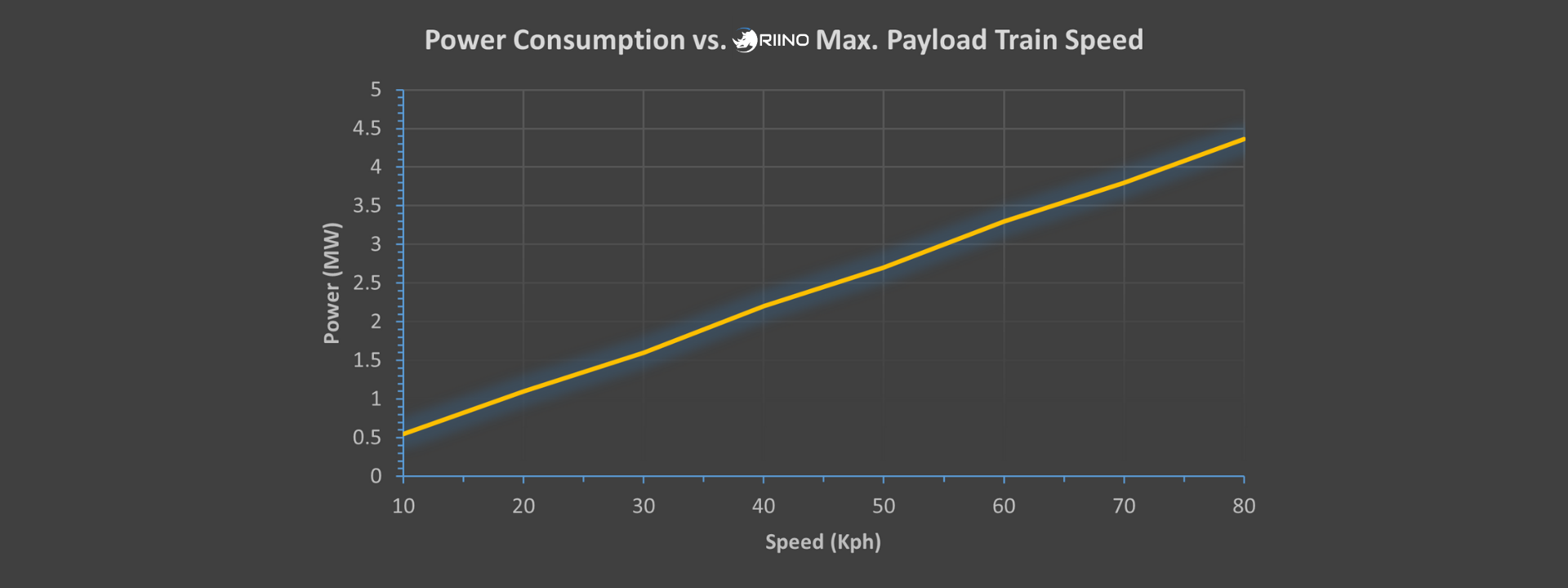

Rail is the most efficient means of transportation Full electric and automated operation No road maintenance Low energy consumption Low maintenance costs Regenerative energy produced Minimal underground ventilation